Polyvinyl Record Company‘s new office on Neil Street is the first new office the record company has had since moving out of co-owner Matt Lunsford’s basement and into its previous location in Downtown Champaign.

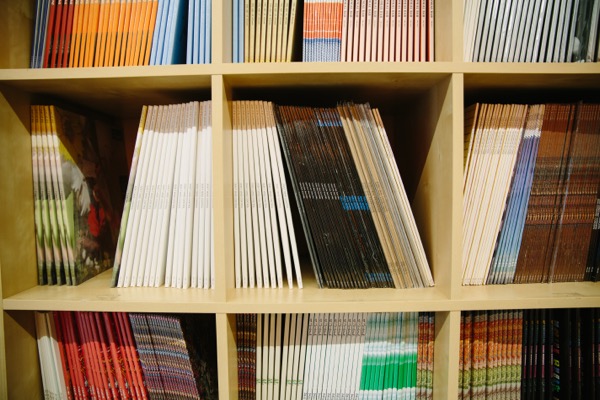

Throughout the label’s 19-year-long existence, it only recently saw a need to move. The old space was small, but cheap and in a nice location. There was ample space to house CDs from the label’s expansive lineup of artists and distro. But unless you’ve been living under a rock for the past decade, you know that CDs aren’t exactly all the rage anymore. Once Polyvinyl began shipping out more and more vinyl records, the size, weight and required conditions of the media became too much for the small space. It was time to move.

“Storing and shipping vinyl is a much bigger challenge, just with the logistics of vinyl,” Lunsford said. “You have to make sure it’s not getting too hot or not being stacked too high. We make sure we ship everything really carefully and package things really well so it doesn’t arrive damaged.”

Now the Polyvinyl office doubles as a warehouse. There’s a garage door in the back so deliveries are no longer the hassle they were in the past. There’s a kitchen and a conference room as well, an upgrade from the single all-purpose table of the previous office.

This move, like the growth of Polyvinyl in the beginning from a Midwestern fanzine into (“completely by accident,” according to Lunsford) a label, and now an international label with a base in Champaign as well as in San Francisco was natural. Lunsford and his wife, co-owner Darcie Knight have, “one step at a time,” evolved their business organically to what it is now.

In an article published on Smile Politely in conjunction with Polyvinyl’s 15th anniversary, John Steinbacher outlined the origins of the label, and in another article, he reached out to artists on the label, like Tim Kinsella (Joan of Arc, etc), Bob Nanna (Braid), Deerhoof and Ranier Maria with questions about being on Polyvinyl.

While Polyvinyl artists usually fall under the indie rock or pop genre, there’s no real restriction on bands the label signs. Typically, they look for a band that works hard and tours; that’s what it’s always been about. Hard work that they can reciprocate.

The work ethic has always been there; it’s how those efforts are allocated that changes. Right now, Polyvinyl works hard to tackle vinyl lead times — something that used to be a routine part of business and is now one of their biggest challenges.

“It is, literally, the bane of our existence,” Lunsford said with a wry smile. “We have daily discussions about it. I feel like it’s been that way for at least the last year to year and a half, and we’ve been doing vinyl production for a long time.”

Now, catalogue records go out of print sometimes to make way for vinyl pressing plants to produce new records. The lead-time for new records at Polyvinyl is about five months—a problem, when your bands are of the touring variety. You can’t exactly sell digital downloads at a show.

“You can literally have a record recorded, and then push it out for [digital] distribution in mere days. Vinyl is the exact opposite. We have records that we could push out for distribution next week, but they are not coming out until February-march because of vinyl production return times,” Lunsford said. “There’s never been such a difference between the speed of the digital world and streaming, what’s completely ubiquitous and normal now, and then the vinyl which is also really popular but takes longer and longer and longer and longer.”

In moving to a bigger space, not only is there more room to back stock vinyl, but more desks. Polyvinyl can expand in manpower, and thus, brainpower. Imagine the problems more heads can solve.

There’s also room for some fun stuff. Lunsford has tossed around the idea of having small, in-house shows on the new patio space, or “pop-up” shops inside, considering the storefront the label has now.

“I think we’re in a good position to grow within the community,” Lunsford said. “Even though we do have a certain degree of very insular work, we are always striving to be community minded for where we are and where we live, and be more of a part of the local music community.”

There’s one part of Polyvinyl that will never change: the Airhead candy included in each and every package shipped out of that office.

“We buy Airheads by the case. It was Darcie’s idea,” Lunsford said.

The candies don’t melt or take up too much space in flat parcels, and the label began including them to reward mail order customers and get them excited about receiving a package. Polyvinyl has been sending out Airheads for so long now that, should an Airhead be accidentally left out of a package, they get an angry email from a candy-deprived customer.

“If there’s ever Airhead production lead-time problems we’re just gonna close the doors!” Lunsford joked. “We can’t handle vinyl production problems and Airhead production problems at the same time.”

Photos courtesy of Justine Bursoni.