“Welcome to the future.”

That’s what Professor Aric Rindfleisch kept repeating on Friday morning at the grand opening of the MakerLab, a 3D printing lab located in the Business Instructional Facility on campus.

In Rindfleisch’s vision of the future, you’ll be able to get up in the morning, tell your 3D printer to make a coffee mug in blue, and watch it materialize before your eyes.

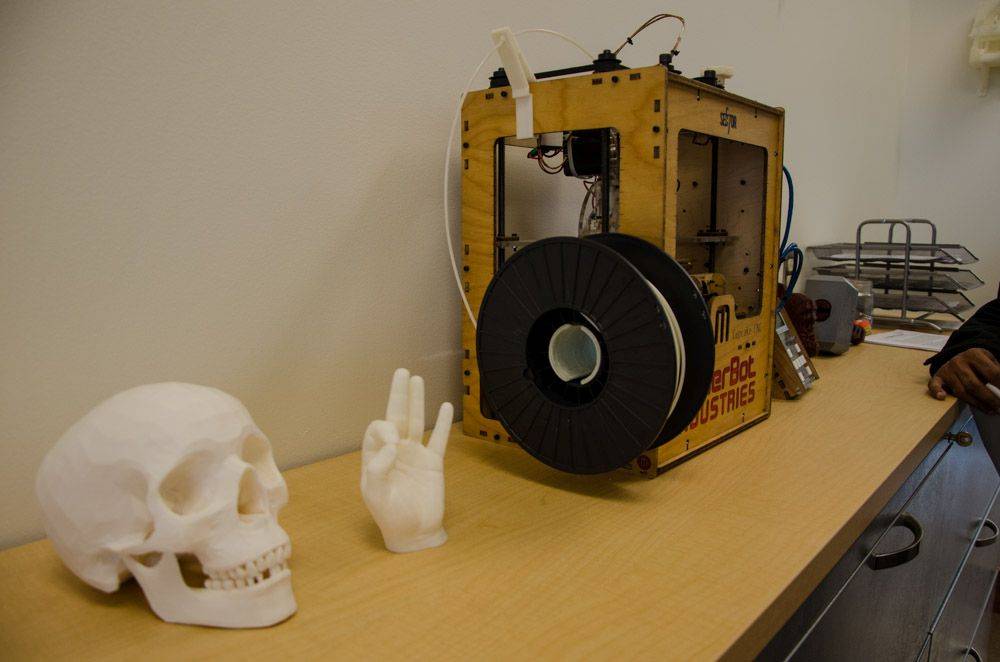

Over the past three years, Rindfleisch has been heavily involved in the 3D printing community and built an early MakerBot printer, “Cupcake,” in 2010. Earlier this year, he co-founded the Illinois MakerLab, the world’s first business school-based 3D printing laboratory.

If 3D printing is the next industrial revolution, the MakerLab puts that power in the hands of students, faculty and the public.

“The idea here was to have an accessible, student-centered experience,” said Vishal Sachdev, assistant professor and director of the Illinois MakerLab.

These aren’t the first 3D printers on campus (engineering, math and computer science all have 3D printers), but those machines are more expensive and not easily accessible to the public.

“These machines are much more low tech—with a little bit of orientation, you can start printing yourself,” said Sachdev.

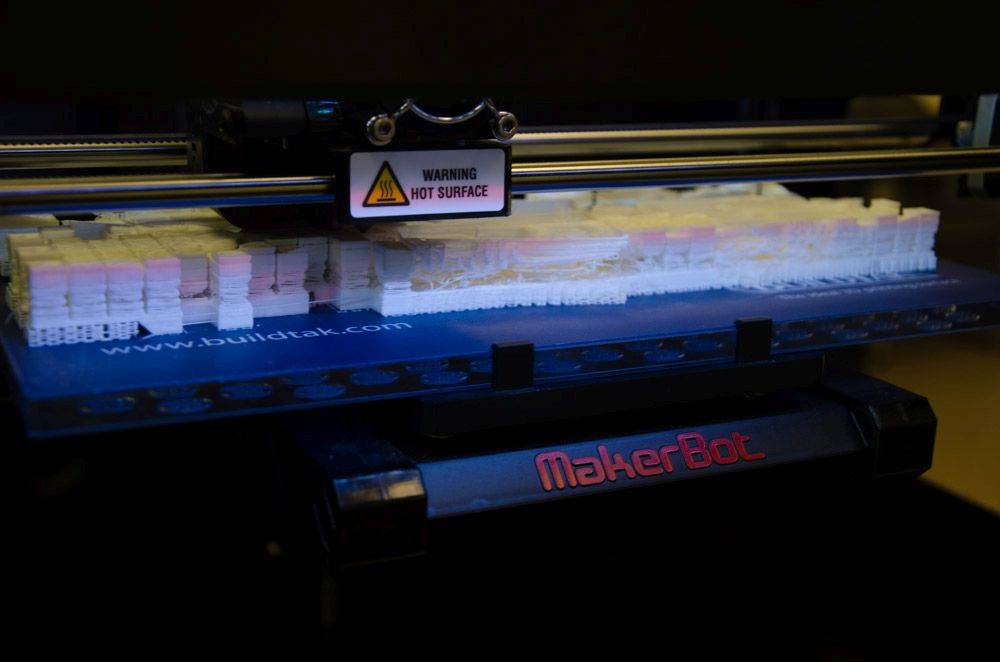

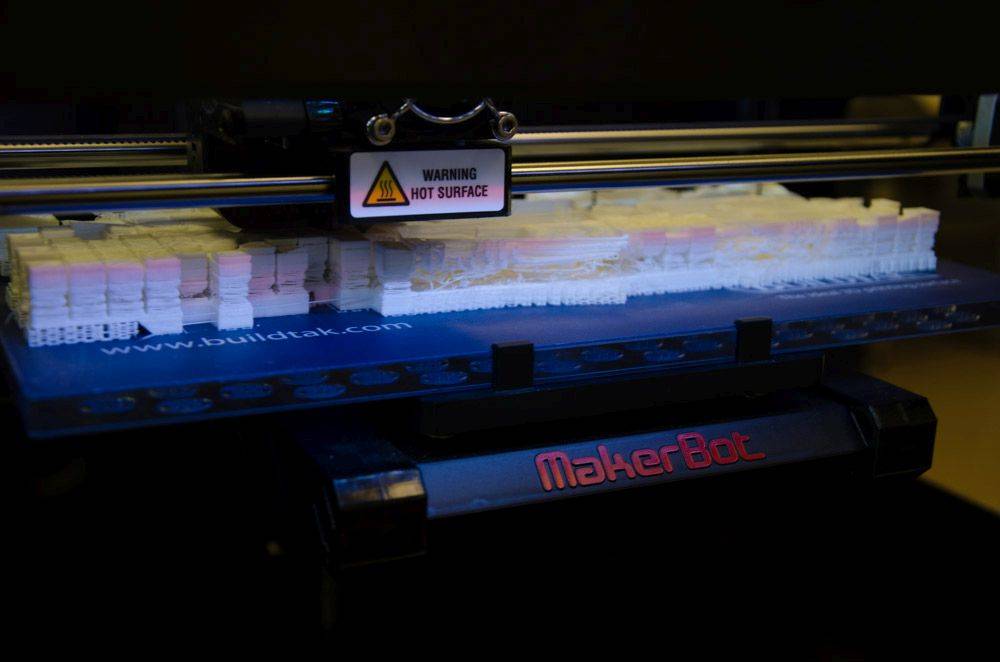

There are 12 MakerBot Replicator 3D printers in the lab and two 3D scanners (a Kinect Scanner and a Digitizer Scanner). The Kinect Scanner is capable of taking 3D scans of anything, including people—you can actually scan yourself and print out your own action figure at the lab within a few hours. The Digitizer Scanner converts physical objects into digital files, like a 3D copy machine.

Over the past six months, about 750 students have come through the lab. Architecture students use the machines to print out building models, kinesiology students use them to print out devices for tracking people’s movements, and art students use them to bring their imaginations to life.

These printers have the potential to change every college experience. Before, architecture students had to build models by hand, using many tiny pieces; now, they just have to create their design on a computer and print it out in 3D.

Prints are priced by weight (5¢ per gram for students, 10¢ per gram for faculty and 15 cents per gram for everyone else) and are surprisingly cheap. A whistle costs a mere 20 cents, and most prints are no more than $2.

The process of printing is pretty simple, but getting a design that doesn’t mess up is trickier, which is why they have “gurus” at the lab to help people out. The gurus are students in marketing, engineering, and other fields who have received training in 3D printing.

One guru, Ryan Hurley, a junior in engineering, explains how the digitizer works.

“The scanner uses a planar light, which reflects off the object; the scanner then counts the wavelength of the beams and records the position. It does that like a million times.”

Anything that can be scanned or designed on a computer can be printed, so the possibilities are practically limitless.

Earlier this month, one of the 3D printers was used to create a replacement part for a 2D printer. Instead of buying a new printer for $250, the MakerLab was able to print a new part for 10 cents. One of the most impressive aspects of 3D printing is their ability to create objects with moving parts, like a wrench or gun, in a single print. Unlike traditional manufacturing techniques, which produce component parts that must be put together. With 3D printing, there is no assembly required.

Dr. Sachdev explains that traditional manufacturing is subtractive, meaning you cut down material to form it into a shape. 3D printers are additive: they create physical objects by layering materials in a successive manner to construct a three-dimensional object. With an additive approach, 3D printers can produce complex designs that are difficult, or impossible, to manufacture traditionally. Plus, there is much less waste.

The MakerLab printers use a type of plastic called PLA, which is made from corn, and comes in a variety of colors from gold to neon orange. The plastics are recyclable, so if you get tired of a model you’ve printed, you can melt it down and create something new.

For all of these reasons, 3D printing has major implications for manufacturing and business in general.

If now you can produce a highly customized product, in a short amount of time, closer to the customer, then you don’t need to worry about finding the lowest cost supplier who will take 6 months to give you a prototype, and take another month to get it produced.

“This could bring some manufacturing back to the States,” Sachdev said. “But not for everything. And this technology doesn’t scale; the next product you make is going to cost the same as the first one.”

MakerLab printers only print in plastic and wood, but commercial printers can make objects from a wider variety of materials, including metal and glass. 3D printers have successfully printed bones as replacement parts, airplane segments all ready to use, and even working guns.

“NASA is saying they’re going to set up a food printer on the moon,” Sachdev said. “You can almost think of it as… what’s food made of? It’s essentially chemicals: proteins, carbs, etc. You just have to synthesize them into the right form and make it look like something human beings would eat.”

Welcome to the future, indeed.

The MakerLab is located in room 3030 of the Business Instructional Facility, 515 East Gregory Drive, Champaign. More information and hours of operation can be found here.

Also, check out this neat video of a 3D printer in action, which was created by the communications unit within the College of Business.